Products

Measuring with 3D technology, ultra-precise measuring equipment, years of design experience and manufacturing partners who share our quality standards. This is the only way to produce customised spare parts for machines where every part is unique and tailored to the application and where every hundredth of a millimetre is crucial.

Reverse engineering: spare parts in original quality

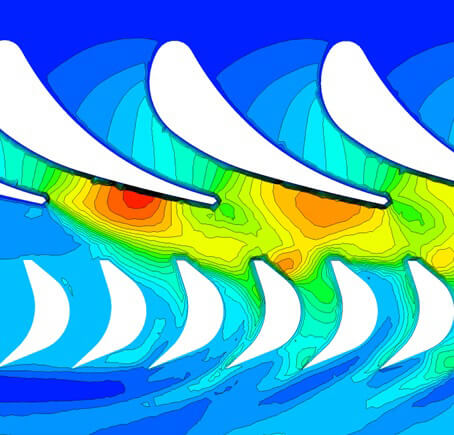

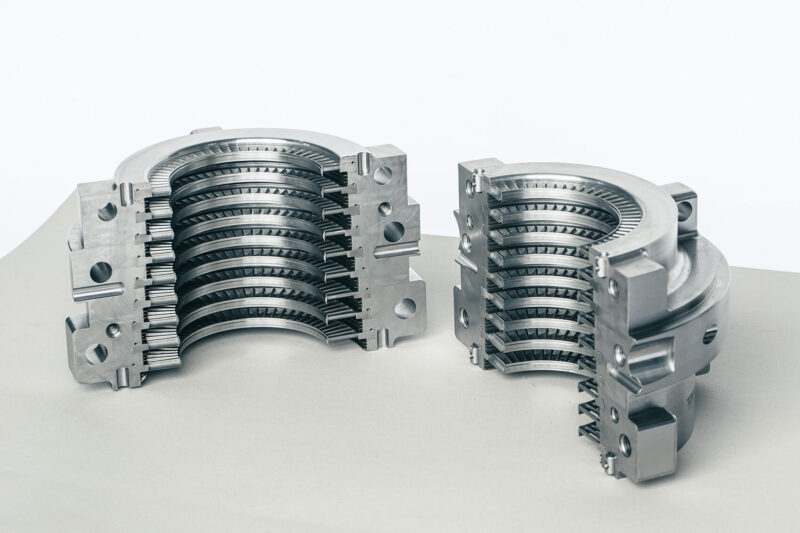

Convincing, independent turbomachinery service does not stop where spare parts are required. As a non-OEM (non-original equipment manufacturer), TST specialises in the production of spare parts based on the principle of reverse engineering. Spare parts for all makes of steam turbines and compressors can thus be manufactured from scratch using a sample part.

The result is a spare part that at least matches the original part in terms of quality, with a wide range of geometric features and the option of optimising it according to the latest findings. Sensible adjustments can be made to the design, the coating, the choice of material or the surface quality.

Interested in a presentation of our manufacturing capabilities? Please do not hesitate to contact us.

Spare parts for steam turbines

Spare parts for turbo compressors

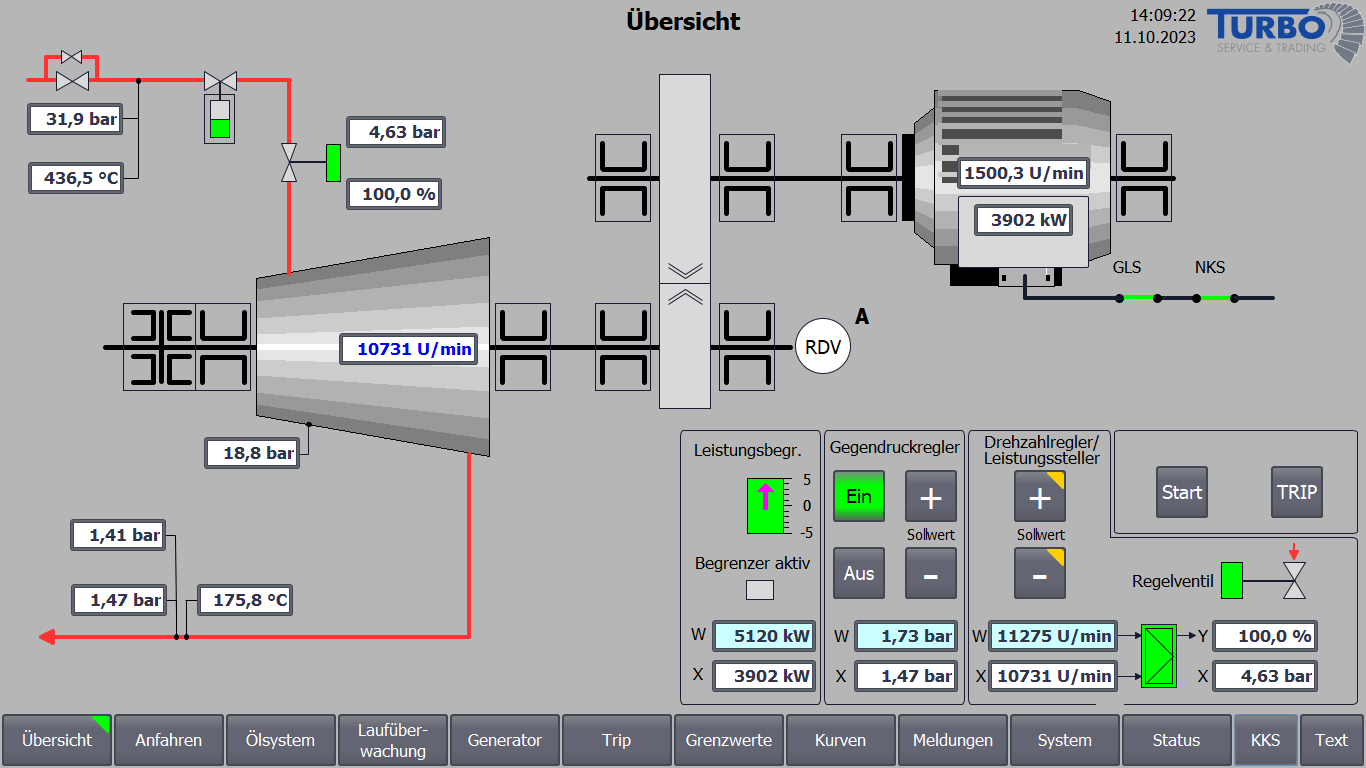

Control systems

In addition to pure mechanics, TST also plans, builds and implements solutions for turbine and compressor control systems. We replace obsolete systems with the latest technical standards and retrofit them as part of conversions – e.g. modified steam extraction – to ensure turbine protection. In doing so, we utilise a network of long-standing suppliers to provide us with the latest hardware and software components.

During the planning and implementation phase, our customers gain an insight into the desired level of technical detail. The customer’s operating personnel receive the necessary training during commissioning.

Let us explain the possibilities with regard to modernisation and conversion in a presentation based on a case study. Please do not hesitate to contact us.

Storage & transport containers

Spare rotors are our customers’ insurance policy that can ensure continued operation and production in the event of damage. The operational readiness and storage conditions of turbine and compressor rotors are correspondingly important.

In addition to its own spare parts production, TST therefore also ensures that components can be stored in storage and transport containers designed for the specific application and manufactured by certified suppliers.

Our technicians and engineers will be happy to work with you to develop the best possible protection for your most important spare parts. We look forward to hearing from you.